Categories

Contact

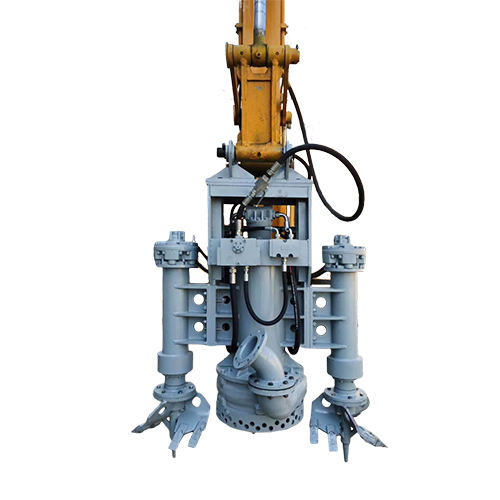

Hydraulic Submersible Slurry Pump

As a leading global Hydraulic Submersible Slurry Pump supplier, we aim to provide procurement experts and distributors with detailed and compelling information about our high-performance pumps. Designed for handling slurry, this hydraulic submersible pump is perfect for challenging environments where reliability and efficiency are paramount.

Our Hydraulic Submersible Slurry Pump is engineered to meet the demands of various industries, ensuring optimal performance and durability. We invite you to explore the features, applications, and advantages of our product, which is backed by our commitment to quality and customer satisfaction.

Technical Drawings and Specifications

Model | Flow (m3/h) | Lift(m) | Matching agitator | Agitator torque | Excavator tonnage |

HDSE200-15 | 200 | 15 | 5.5kW | 1556 | 10T-20T |

HDSE150-30 | 150 | 30 | |||

HDSE300-20 | 300 | 20 | |||

HDSE400-10 | 400 | 10 | 7.5kW | 1946 | 20T-30T |

HDSE500-15 | 500 | 15 | |||

HDSE250-35 | 250 | 35 | |||

HDSE300-30 | 300 | 30 | 15kW | 2433 | 30T-40T |

HDSE400--30 | 400 | 30 | |||

HDSE400-40 | 400 | 40 |

Specifications

Parameter | Value |

Flow Rate | Up to 2000 m³/h |

Head | Up to 50 meters |

Power Rating | 10 - 200 kW |

Material | High-Chrome Alloy, Stainless Steel |

Operating Temperature | -20°C to 120°C |

Max. Solid Size | Up to 100 mm |

Product Features

Our Hydraulic Submersible Slurry Pump is designed with the following key features:

1.High Efficiency: Optimized hydraulics ensure maximum flow and minimal energy consumption.

2.Durability: Constructed from wear-resistant materials such as high-chrome alloy and stainless steel.

3.Robust Design: Capable of handling solids and abrasive materials.

4.Versatility: Suitable for various applications across multiple industries.

5.Easy Maintenance: Simplified design for quick servicing and minimal downtime.

6.Compact and Portable: Easy to deploy and transport to different job sites.

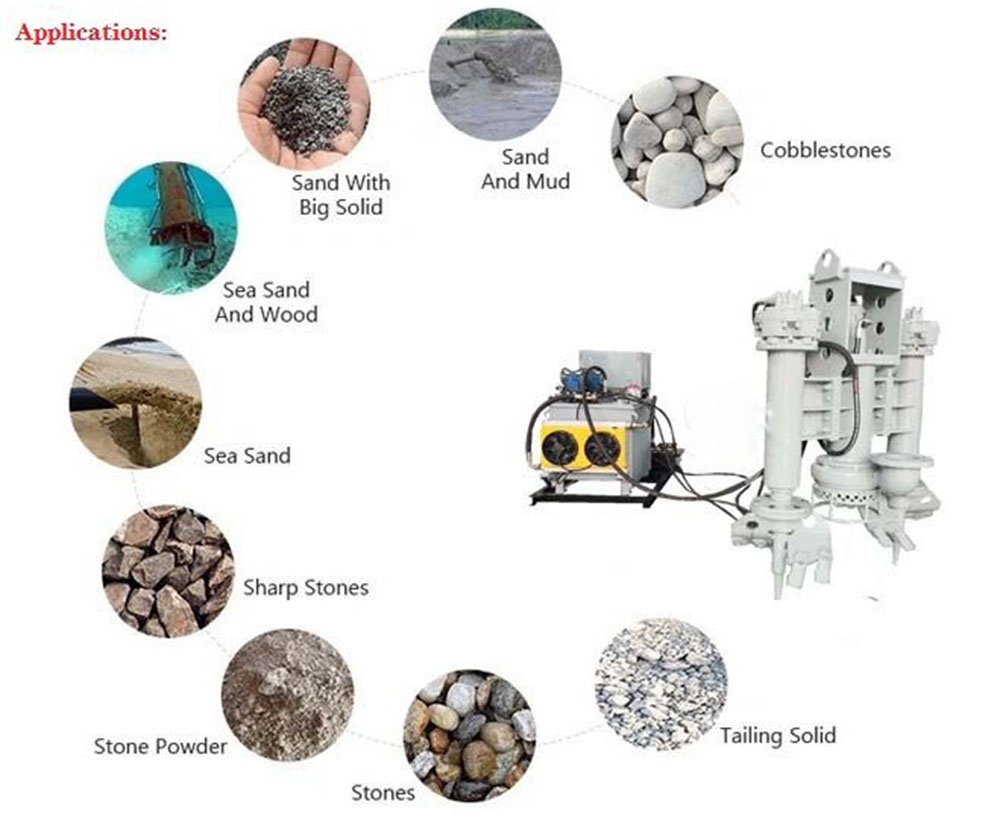

Hydraulic Submersible Slurry Pump Applications

The Hydraulic Submersible Slurry Pump is ideal for a wide range of applications, including:

1.Mining: Handling slurry and sediment in mining operations.

2.Construction: Dewatering and slurry removal at construction sites.

3.Municipal: Wastewater and sewage management.

4.Industrial: Processing slurry in manufacturing and other industrial processes.

5.Marine: Dredging and sediment removal in marine environments.

Quality Assurance

We ensure the highest quality standards for our Hydraulic Submersible Slurry Pump through:

1.Stringent Manufacturing Processes: Utilizing advanced technology and high-quality materials.

2.Comprehensive Quality Control: Rigorous testing and inspection procedures.

3.After-Sales Support: Dedicated customer service and technical support.

Warranty and Service

We offer a robust warranty and service package for our pumps, including:

1.Extended Warranty: Coverage for manufacturing defects and performance issues.

2.Maintenance Plans: Regular servicing to keep your pump in optimal condition.

3.Technical Support: Expert assistance available for troubleshooting and repairs.

Customization Services

We provide customization options to meet specific needs:

1.Tailored Designs: Custom specifications based on your requirements.

2.Consultation and Support: Contact us for a personalized quote and technical assistance.

Product Certifications

Our pumps comply with relevant industry standards and certifications, ensuring reliability and safety.

Company Introduction

Tianjin Kairun Pump Co., Ltd. is a renowned pump manufacturing enterprise specializing in product research and development, manufacturing, and non-standard product customization. Located in the Tianjin Baodi industrial zone, we offer a wide range of pumps and system components, ensuring comprehensive solutions for various applications.

Factory Showcase

Contact Information

Phone: +86 15003222152

Email: catherine@mstpump.cn

FAQ

1.What information is needed to offer ?

Liquid:___

Capacity:___ m3/hr

Head: ___ m

PH:___

Specific of gravity:___

Voltage:___V, Frequency:___hz

2. What material pump can you supply?

A05, Natural rubber, ceramics, polyurethane etc.

3. Can you supply special or OEM parts?

Yes, please send me the detailed drawing or parts code to check.

4.What is the delivery time?

7-15 days for normal pumps.