Categories

Contact

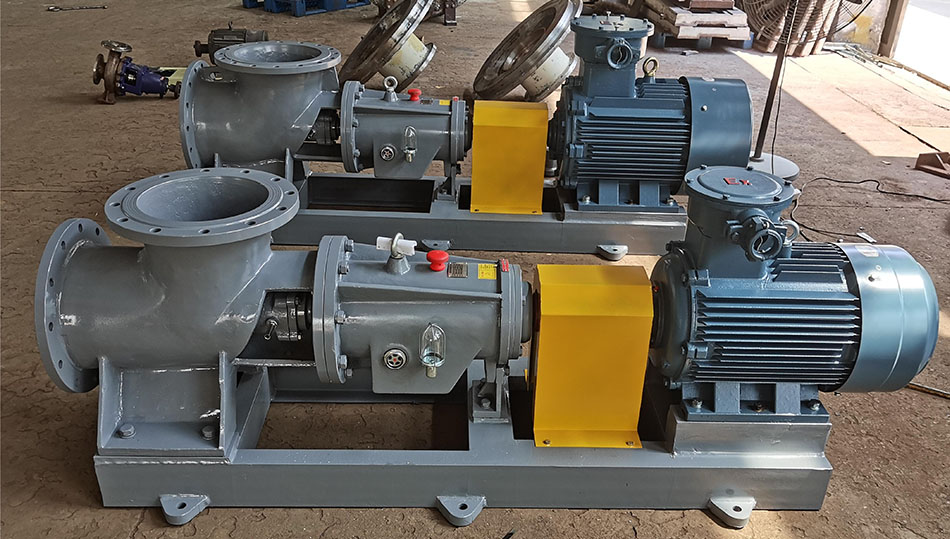

Horizontal Axial Flow Pumps

Horizontal axial flow pumps are indeed designed to handle large volumes of fluid, making them indispensable in various industrial and agricultural applications.

Capacity and Flow Rate

Horizontal axial flow pumps are characterized by their ability to move significant quantities of fluid at high flow rates. The capacity of these pumps depends on several key factors:

Impeller Size and Design: The impeller in horizontal axial flow pumps is crucial as it determines how much fluid can be moved per unit of time. Larger impellers with optimized blade designs can enhance the pump's efficiency and capacity to handle higher flow rates.

Pump Casing Diameter: The diameter of the pump casing also plays a role in determining the pump's capacity. A larger casing diameter typically allows for greater fluid throughput.

Operating Speed: The rotational speed of the pump (RPM) influences its capacity. Higher speeds can increase flow rates, but must be balanced with efficiency and wear considerations.

Applications:

Horizontal axial flow pumps find extensive use in several key applications where high flow rates and efficient fluid movement are essential:

Irrigation: In agriculture, these pumps are vital for distributing water across large fields. They ensure that crops receive adequate irrigation, promoting optimal growth and yield.

Flood Control: During flood events, horizontal axial flow pumps can rapidly evacuate large volumes of water from flood-prone areas, helping to mitigate flood damage and protect infrastructure and communities.

Model | Vane Angel | Capacity (m3/h) | Head (m) | Power (KW) | Speed (r/min) | Effciency (%) | Outer diameter of impeller (mm) |

350QZ-50G | 0° | 1173.6 | 10.1 | 55 | 1450 | 81.8 | 300 |

350QZ-100D | 0° | 802.9 | 1.92 | 11 | 1450 | 79.5 | 300 |

500QZ-50G | 0° | 2677 | 10.38 | 110 | 980 | 83.3 | 450 |

600QZ-50 | 0° | 3690.7 | 8.84 | 132 | 740 | 83.7 | 550 |

700QZ-75 | 0° | 5451.5 | 7.33 | 160 | 740 | 83.9 | 600 |

800QZ-100 | 0° | 6140.9 | 3.79 | 110 | 590 | 83.8 | 700 |

900QZ-160D | 0° | 9961.5 | 2.29 | 110 | 490 | 82.4 | 850 |

1000QZ-35 | 0° | 11571.5 | 15.67 | 630 | 490 | 85.8 | 870 |

1200QZ-135 | 0° | 13737.2 | 3.72 | 250 | 490 | 84.4 | 950 |

1300QZ-50 | 0° | 16868.8 | 9.66 | 630 | 370 | 86 | 1150 |

1400QZ-100 | 0° | 19401.3 | 4.39 | 400 | 370 | 85.7 | 1200 |

1600QZ-75 | 0° | 32616.3 | 7.09 | 900 | 295 | 86.5 | 1480 |

Cooling Water Circulation: Power plants and industrial facilities use horizontal axial flow pumps for circulating cooling water. They efficiently transfer heat away from equipment and processes, maintaining optimal operating temperatures.

Water Transfer: They are also employed in municipal water supply systems for pumping water from reservoirs to treatment facilities or distribution networks.

Advantages:

High Efficiency:Horizontal axial flow pumps are designed for efficient fluid movement with minimal energy loss, making them cost-effective for applications requiring continuous operation.

Versatility: They can handle various types of fluids, from clean water to liquids with suspended solids, depending on the impeller design and casing configuration.

Reliability: Their robust design and straightforward operation contribute to reliability, even under demanding conditions such as high flow rates and prolonged use.

Flow Control

When trying to get the most out of Horizontal axial flow pumps, efficient flow control is absolutely necessary. The flow rate and pressure of these pumps are frequently controlled by adjusting blades or vanes.

Operators can tailor the pump's performance to meet the application's specific needs by adjusting the angle of the blades.

Applications where the demand for water or fluid flow changes over time benefit most from this flexibility.

Variable speed drives, or VSDs, can be used to control flow in addition to adjustable blades. The flow rate can be controlled by adjusting the pump's operating speed with VSDs.

Because it eliminates the need for mechanical adjustments and enables precise control of the pump's output, this method is extremely effective.

A VSD, for instance, can adjust the speed of the horizontal axial flow pumps in a cooling water circulation system to match the cooling load, ensuring optimal performance and energy savings.

Throttling valves are an additional method of controlling flow. The flow rate can be decreased by partially closing these valves, but this method is less effective than using VSDs or adjustable blades. Throttling may result in increased wear and tear on the pump's components over time and introduce additional friction losses. As a result, it is usually used as a secondary or temporary flow control measure.

Operation in Two Directions

The ability of Horizontal axial flow pumps to operate in two directions is one of their distinctive characteristics. In some applications, this bidirectional operation can be beneficial because it offers more flexibility and functionality.

In drainage and irrigation systems, for instance, the pump can be used to move water into and out of storage reservoirs as needed.

This ability is especially useful for controlling the amount of water in the ground during periods of heavy rain or drought.

The pump's impeller and casing are made to handle fluid flow in both directions to make bidirectional operation easier. The pump's efficiency and performance are guaranteed to remain constant regardless of the flow direction thanks to this design.

The pump's components must be properly maintained and inspected on a regular basis to guarantee reliable operation in both directions.

Efficiency in High Flow Applications

In situations where high flow rates and low to moderate pressure heads are required, Horizontal axial flow pumps are extremely effective.

Because of their low energy consumption, they are a cost-effective option for moving a lot of fluid.

These pumps' straight-through flow path reduces turbulence and friction, two common causes of efficiency loss in other types of pumps.

The effectiveness of horizontal axial flow pumps in flood control and other high-flow applications can result in significant energy savings.

A flood control system with these pumps, for instance, can move a lot of water quickly and effectively, lowering the risk of flooding and lowering operating costs.

Similarly, these pumps' high efficiency in agricultural irrigation ensures that water is evenly distributed across large fields, promoting healthy crop growth and reducing water waste.

The high efficiency of horizontal axial flow pumps is due to a number of factors.

The impeller and casing's streamlined design reduces fluid flow resistance, and cutting-edge materials and coatings reduce wear and tear.

In addition, modern horizontal axial flow pumps frequently optimize their performance by incorporating cutting-edge technologies like computational fluid dynamics (CFD). By simulating and analyzing the pump's flow patterns using CFD, engineers can find areas for improvement and boost efficiency overall.