Categories

Contact

Axial Flow Pumps Factory

Axial flow pumps are essential components in various industrial and agricultural applications, designed to move large volumes of fluid efficiently. These pumps are characterized by their unique operating principle, which allows for high flow rates at relatively low head pressures.

Kairun factory’s axial flow pump is the preferred choice of water management experts and global distributors who demand high-performance, reliable solutions. Designed for applications where large volumes of water need to be moved efficiently, our pumps are ideal for irrigation, flood control, power plants, and industrial water transfer.

Key Features

1.High-efficiency impeller design for optimal water flow

2.Robust construction using durable materials such as cast iron and stainless steel

3.Low maintenance requirements due to simple and reliable design

4.Wide range of flow rates and head pressures to suit various applications

5.Compact and space-saving horizontal installation

6.Available in different sizes and configurations to meet specific customer needs

Fluid Flow Direction

The direction in which fluid flows through an axial flow pump is its distinguishing feature. The fluid enters and exits these pumps parallel to the impeller's axis of rotation. In contrast to centrifugal pumps, where the fluid enters axially but exits radially, this axial flow pattern occurs.

The unique design of the pump's components, particularly the impeller and the casing, allows for the axial flow direction. The impeller blades, which are designed to direct the flow along the pump's axis, direct the fluid as it enters the system. Compared to other pump types, this design enables the efficient movement of large volumes of fluid with little direction change, resulting in lower energy losses.

Technical Drawings and Specifications

Model | Vane Angle | Capacity (m³/h) | Head (m) | Power (Kw) | Speed (r/min) | Efficiency (%) | Outer diameter of impeller (mm) |

600QH-40 | 0° | 4415.2 | 14.09 | 250 | 740 | 84.1 | 550 |

700QH-72 | 0° | 5056.1 | 6.54 | 160 | 740 | 84.2 | 600 |

800QH-35 | 0° | 7257.4 | 14.71 | 400 | 590 | 85.1 | 700 |

1000QH-40 | +2° | 12461.6 | 16.52 | 710 | 490 | 86.2 | 870 |

1200QH-72 | +4° | 15607 | 8.45 | 560 | 490 | 85.8 | 950 |

1300QH-72 | -2° | 17024 | 4.4 | 400 | 370 | 84.6 | 1150 |

1400QH-72 | -4° | 15815 | 5.99 | 450 | 370 | 84.9 | 1200 |

600QZ-50 | 0° | 3690.7 | 8.84 | 132 | 740 | 83.7 | 550 |

700QZ-75 | 0° | 5451.5 | 7.33 | 160 | 740 | 83.9 | 600 |

800QZ-100 | +2° | 6513.1 | 3.99 | 132 | 590 | 84.2 | 700 |

1000QZ-135 | +4° | 12167.9 | 3.41 | 200 | 490 | 82.5 | 870 |

1200QZ-160 | -2° | 11975.7 | 2.85 | 160 | 490 | 83.9 | 950 |

1300QZ-50 | -4° | 12936.2 | 8.9 | 450 | 370 | 82.2 | 1150 |

1400QZ-100 | 0° | 16426.4 | 6.51 | 400 | 370 | 82.6 | 1200 |

1600QZ-135 | +2° | 29598.3 | 4.88 | 560 | 295 | 82.6 | 1480 |

Contact email catherine@mstpump.cn for more axial flow pump models.

Impeller Design

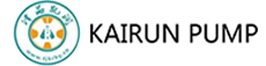

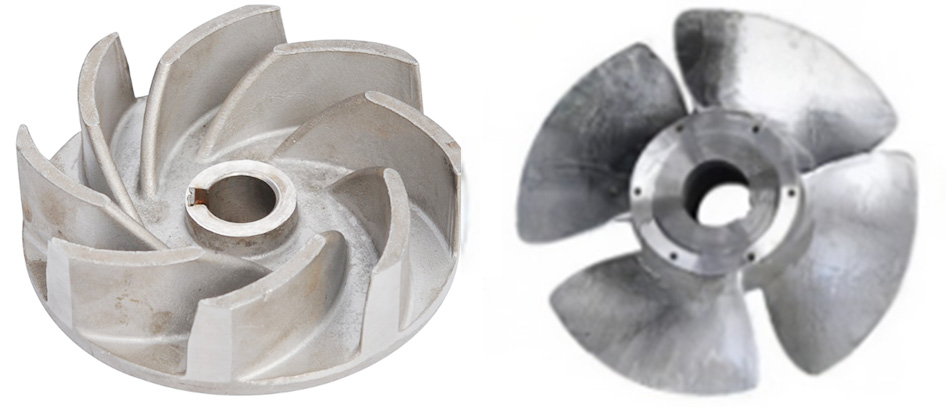

The impeller is the heart of an axial flow pump, and its design plays a crucial role in determining the pump's performance characteristics. Axial flow pump impellers are distinctly different from those found in centrifugal pumps, reflecting their unique operating principle.

The typical impeller resembles a propeller or fan blade. It consists of multiple blades arranged around a central hub, with each blade designed to guide the fluid along the pump's axis. The number of blades can vary depending on the specific pump design and application requirements, but typically ranges from three to six blades.

The blade profile is carefully engineered to optimize fluid flow and pump efficiency. The leading edge of the blade, where the fluid first contacts the impeller, is usually designed with a smooth, rounded profile to minimize turbulence and cavitation risks. The blade then curves gently, guiding the fluid through the pump while imparting kinetic energy.

One key feature of axial flow pump impellers is their relatively small diameter compared to the pump casing. This design allows for a large open flow area, which is crucial for handling high flow rates with minimal resistance. The small diameter also contributes to the pump's compact design, making it suitable for applications where space is limited.

Application Areas

Axial flow pumps find widespread use across various industries due to their ability to move large volumes of fluid efficiently at relatively low head pressures. Their unique characteristics make them particularly suitable for certain applications where other pump types may be less effective or efficient.

One of the primary application areas for axial flow pumps is in water management and flood control. These pumps are often used in stormwater pumping stations, where they can quickly move large volumes of water to prevent flooding in urban areas. Their high flow capacity allows them to rapidly clear excess water during heavy rainfall events or storm surges.

In agriculture,it plays a crucial role in irrigation systems. They are used to draw water from rivers, lakes, or reservoirs and distribute it across large agricultural areas. The high flow rates achievable with these pumps make them ideal for supplying water to extensive irrigation networks efficiently.

The wastewater treatment industry is another significant user of axial flow pumps. In treatment plants, these pumps are often employed in the initial stages to move large volumes of raw sewage or partially treated water between different treatment processes. Their ability to handle fluids containing small solid particles without significant loss of efficiency makes them particularly suitable for this application.

Cooling systems in power plants and large industrial facilities frequently utilize axial flow pumps. These pumps are used to circulate large volumes of cooling water through heat exchangers, condensers, and cooling towers. The high flow rates and relatively low head pressures required in many cooling applications align well with the characteristics.

In the maritime industry, axial flow pumps find applications in various shipboard systems. They are used for ballast water management, firefighting systems, and general seawater pumping applications. The compact design of these pumps makes them suitable for installation in the limited space available on ships.

Axial flow pumps are also used in the oil and gas industry, particularly in offshore applications. They are employed for seawater lift, providing cooling water and supplying water for injection into oil reservoirs to maintain pressure.

In the mining industry, it is used for dewatering operations, helping to remove excess water from mine sites and quarries. Their high flow capacity allows for efficient water removal, which is crucial for maintaining safe and productive mining operations.

The aquaculture industry utilizes axial flow pumps for circulating and aerating large volumes of water in fish farms and other aquaculture facilities. The gentle handling of water by these pumps helps maintain a suitable environment for aquatic life.

Axial Flow Pump for Sale

Tianjin Kairun offers customization options to meet the unique needs of our customers. If you are choosing your axial flow pump manufacturers, welcome to contact us at catherine@kairunpump.com.

When considering the purchase of the pump, it's crucial to select a manufacturer with a proven track record of quality and reliability. Tianjin Kairun has established itself as a reputable supplier in the pump industry, offering a range of axial flow pump solutions suitable for various applications.

One of the key advantages of working with Tianjin Kairun is their ability to provide customized solutions. This flexibility allows customers to obtain pumps that are precisely tailored to their specific operational requirements, potentially improving efficiency and reducing long-term costs.

Company Profile

Tianjin Kairun Pump Industry Co., Ltd. is a pump manufacturing company engaged in product research and development, processing and manufacturing, transformation projects, and non-standard product customization.

The mainly products of Kairun is submersible axial (mixed) flow pumps, vertical axial flow pumps, submersible sewage pumps, submersible slurry pumps, special pumps for mines, vertical long-shaft pumps, and Submersible agitator etc., we could provide system supporting facilities such as pipe fittings, valves, electric control cabinets, and power equipment.

The technical engineers can independently develop, design, research and produce a variety of water pump products, and have the ability to customize and develop non-standard products.

We always insists on survival by quality, development by focusing on products, integrity as the cornerstone, and satisfying customer needs as the service purpose, providing customers with satisfactory technical support and perfect supporting services.

Company philosophy: integrity, professionalism, quality, service

Certifications

Our pumps are certified to meet relevant industry standards, ensuring their quality, safety, and performance.

FAQ

1.What is the lead time for ordering axial flow pumps?

Within 15 workdays, Off Season Lead Time: within 15 workdays:

2.Can you provide installation and commissioning services?

Yes,we can provide installation and commissioning services

3.What is the warranty period for your pumps?

1 Year warranty.

4.How do I request a quote for a customized axial flow pump?

Contact Information

For more information about our pump or to discuss your specific requirements, please contact us:

Phone:+86 15003222152

Email:catherine@mstpump.cn